3D Printing Service: Bring Your Ideas to Life with Fast and Precise Manufacturing

3D printing is no longer just a futuristic concept—it’s a powerful tool revolutionizing manufacturing and product development. With its ability to create complex designs quickly and precisely, 3D Printing Service (3D Druck Service) has become one of the most sought-after technologies across industries. What makes it even more appealing is the way it empowers businesses and individuals alike to bring their ideas to life in ways that weren’t possible before.

This article explores the key benefits of 3D printing services, focusing on why this technology is trending and gaining momentum as one of the most impactful innovations.

The Power of 3D Printing in Modern Manufacturing

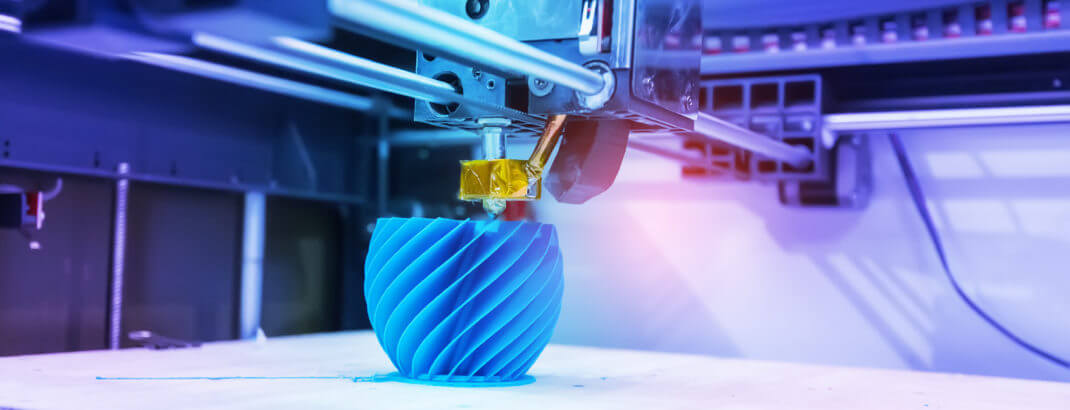

3D printing, or additive manufacturing, has grown exponentially over the past decade. Its appeal lies in its ability to transform digital designs into physical objects—layer by layer—using materials such as plastics, metals, and resins. Unlike traditional manufacturing methods, there are no molds or castings required, making the process flexible and fast.

According to industry statistics, the global market size for 3D printing was valued at $15.2 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 23.3% through 2030. Its applications span a myriad of industries, from automotive and aerospace to healthcare, education, and consumer products. But what exactly makes 3D printing services so beneficial?

Fast Prototyping Speeds Up Development

One of the most significant advantages of 3D printing is its speed. Traditional manufacturing often requires weeks or even months to create molds, tools, or prototypes. With 3D printing services, concepts can be transformed into realistic prototypes in a matter of days. This rapid turnaround allows businesses to test and refine ideas more efficiently before committing to full-scale production.

For instance, in industries like healthcare, the ability to 3D print custom prosthetics or surgical tools in record time can make a significant difference in patient outcomes. Similarly, product designers benefit hugely from being able to iterate and improve upon their designs without months-long delays, enabling them to stay competitive in fast-moving markets.

Cost-Effective Manufacturing Solutions

Unlike conventional manufacturing methods, 3D printing eliminates the need for costly tooling and molds. This makes it particularly attractive for small businesses, startups, and entrepreneurs who may not have the capital to invest in expensive manufacturing machinery. With 3D printing, they pay solely for the creation of the desired object, avoiding the overhead associated with traditional methods.

Additionally, because the additive manufacturing process only uses the necessary amount of material for each piece, waste is drastically reduced. This stands in stark contrast to subtractive methods, like CNC machining, where excess material is discarded. This cost-effectiveness extends to low-volume production runs, ensuring that even small batches remain financially viable.

High Precision and Customization

The precision of 3D printing technology allows for the creation of intricate designs and complex geometries that would be nearly impossible with traditional manufacturing methods. This opens up new possibilities for customization, as products can be tailored to the specific needs or preferences of individual customers.

Customization has become a game-changer in industries like fashion, jewelry, and even dental care. Personalized dental aligners, for example, rely heavily on 3D printing to achieve the exact shape and fit needed for each patient. This level of precision not only improves the function of the end product but also enhances its aesthetic appeal.